CoLink Material Technology Co., Ltd. - Driven by a Passion for Technological Innovation and Sustainable Development.

This vision originated from the in-depth research in material technology by COHO Group and a keen insight into future societal energy demands and environmental trends. Driven by this motivation, the founding team of CoLink has assembled professionals from various fields, dedicating themselves to creating a brand focused on the research and application of materials for energy sustainability.

Materials play a critical role in modern technology and industry; hence, the brand’s mission is to provide customers with high-performance, high-stability solutions. From carefully selected and developed materials such as ZTA (Zirconia Toughened Alumina) ceramic substrates, AlN (Aluminum Nitride) ceramic substrates to AlSiC (Aluminum Silicon Carbide), these materials exhibit excellent thermal conductivity, insulation, high-temperature resistance, corrosion resistance, making them widely applicable in energy conversion, electronic devices, and the automotive industry.

CoLink will continue its efforts to drive technological advancement, offering more advanced and environmentally friendly material solutions to global customers, addressing the ever-evolving challenges on a global scale.

ZTA Substrates

ZTA (Zirconia Toughened Alumina) is a versatile composite ceramic composed of alumina ceramic reinforced with zirconia particles. This unique combination enhances the inherent qualities of pure alumina, resulting in significant improvements. The fusion of these materials imparts higher fracture toughness, flexural strength, and dielectric strength to the substrate, providing exceptional durability under mechanical stress. Notably, the thermal conductivity of ZTA exceeds 27 W/mK, and its flexural strength reaches 700 MPa. Its excellent thermal conductivity, high-temperature resistance, and insulating properties make it an ideal choice for applications in passive components and chip resistors.

AlN Substrates

AlN (Aluminum Nitride) substrates stand out due to their exceptional thermal and electrical properties. With thermal conductivity ranging from 170 to 230 W/mK, these substrates offer excellent wear resistance and oxidation resistance. These characteristics make AlN highly compatible with high-performance electronic products, finding extensive applications in fields such as trains, railways, and high-power density modules. Additionally, the coefficient of thermal expansion of aluminum nitride substrates can be matched with chip materials, further emphasizing their practicality as insulating materials in power modules. With its remarkable thermal conductivity, superior high-temperature resistance, and insulation capabilities compared to traditional PCB materials, AlN is an ideal choice for integration into high-power LEDs and passive components like chip resistors.

AlN Thermal pads

AlN Thermal pad is a thermally conductive compound with AlN (Aluminum Nitride) as the primary filler material. Due to the high thermal conductivity and electrical insulation properties of aluminum nitride, AlN thermal silicone becomes an ideal thermal management material in applications requiring efficient heat dissipation and electrical insulation. This silicone is typically used in heat dissipation for electronic components, chip packaging, and power modules, providing an effective solution for improving device performance and extending its lifespan.

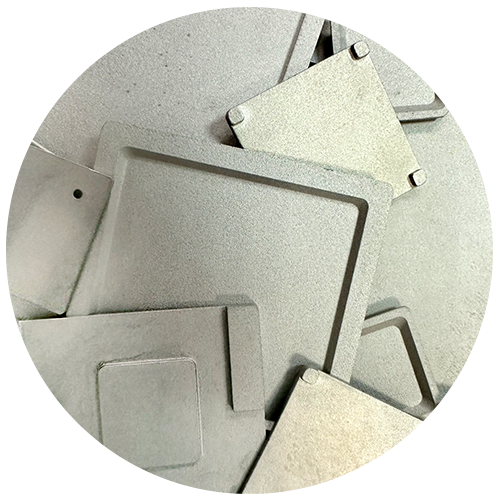

AlN Custom components

CoLink offers customized structural components based on AlN (Aluminum Nitride) materials, meeting the demands of various industries for high-efficiency heat dissipation, electrical insulation, and highly durable materials. Our products are widely applied in fields such as electronics, semiconductors, power modules, LEDs, and communication equipment, ensuring stability and reliability in high-temperature, high-pressure, and high-frequency environments.

AlO Substrates

AlO (Al₂O₃) substrates are widely used in the electronics and industrial sectors due to their excellent mechanical strength, thermal stability, and insulation properties. Alumina substrates are often employed in electronic component packaging, heat dissipation, and insulation solutions in high-temperature and harsh environments. Additionally, the material’s relatively low cost offers great cost-effectiveness.

AlSiC Heat sinks

MMC (Metal Matrix Composite) products, such as AlSiC (Aluminum Silicon Carbide), are widely used in high-speed rail, subways, aerospace, new energy vehicles, wind power generation, and consumer electronics. Existing IGBT packages typically use copper or aluminum as the backplate, whereas IGBT packages with AlSiC backplates offer significant advantages over commonly used backplate materials. These advantages greatly enhance the reliability of power devices and ensure better thermal expansion matching, as the thermal expansion coefficient closely matches that of semiconductor wafers and ceramic substrates.

The Preferred Choice for Business Partners

CoLink, a brand under the COHO Group, has over 20 years of manufacturing experience and is your trusted professional manufacturer. We take pride in our technology and exceptional quality, which have earned the trust of numerous customers. By partnering with us, you will experience the perfect combination of professionalism, efficiency, and innovation, working together to create outstanding products that lead the industry.

Contact us now to initiate collaboration, and let us work together to achieve excellence for your products, building a brighter future together!