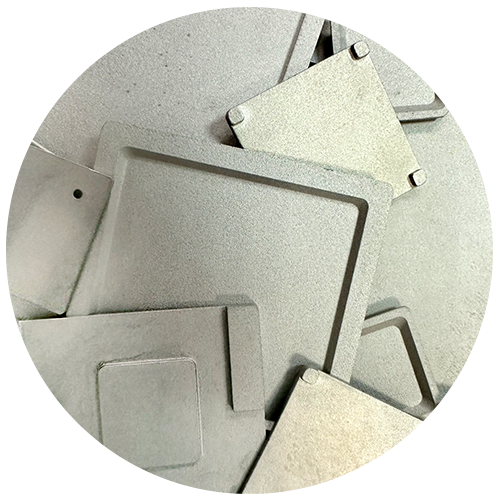

AlSiC Heat sinks

MMC (Metal Matrix Composite) products, such as Aluminum Silicon Carbide (AlSiC), are widely used in high-speed rail, subways, aerospace, new energy vehicles, wind power generation, and consumer electronics. Traditional IGBT packaging typically utilizes copper or aluminum as the baseplate. However, compared to these commonly used baseplate materials, IGBT packaging with an AlSiC baseplate offers several advantages, significantly enhancing the reliability of power devices and improving thermal expansion compatibility. The coefficient of thermal expansion (CTE) of AlSiC is highly compatible with semiconductor wafers and ceramic substrates.

AlSiC has a wide range of applications due to its excellent thermal performance, mechanical strength, and lightweight properties. Below are some key application areas of AlSiC:

▽ High-Power Electronic Devices

AlSiC is widely used in IGBT (Insulated Gate Bipolar Transistor) substrates and other power modules because its coefficient of thermal expansion (CTE) matches that of semiconductor materials such as silicon and gallium nitride. This compatibility minimizes thermal stress caused by expansion mismatches and provides exceptional thermal dissipation.

▽ Thermal Management

In high-power-density electronic devices, AlSiC is commonly used for heat sinks and thermal substrates. Its high thermal conductivity and low thermal expansion make it suitable for applications requiring efficient heat dissipation, such as power converters, laser diodes, and power amplifiers.

▽ Optoelectronic Devices

In silicon photonics technology, AlSiC serves as a silicon photonic carrier due to its outstanding thermal stability and mechanical properties, making it an ideal material for high-speed data transmission and optical communication devices.

▽ Aerospace and Military Applications

AlSiC is utilized in aerospace and military sectors for manufacturing lightweight, high-strength structural components and electronic enclosures. It is particularly suitable for high-performance equipment operating in extreme temperature environments.

▽ Automotive Electronics

AlSiC substrates are widely used in power electronic systems of electric and hybrid vehicles, such as inverters and battery management systems. Its excellent thermal dissipation and low expansion characteristics enhance the reliability and lifespan of automotive electronic systems.

▽ Consumer Electronics

Due to its lightweight nature and effective heat dissipation, AlSiC is increasingly used in high-performance consumer electronics, such as premium laptops and servers.

▽ Semiconductor Packaging

In advanced packaging technologies, AlSiC is used as a substrate and reinforcement ring. These components require high strength and low thermal expansion to improve package reliability and longevity.

AlSiC provides solutions for various applications requiring superior thermal performance and mechanical strength. It plays a crucial role in key technologies across industries such as electronics, automotive, and aerospace.

The Preferred Choice for Business Partners

CoLink, a brand under the COHO Group, has over 20 years of manufacturing experience and is your trusted professional manufacturer. We take pride in our technology and exceptional quality, which have earned the trust of numerous customers. By partnering with us, you will experience the perfect combination of professionalism, efficiency, and innovation, working together to create outstanding products that lead the industry.

Contact us now to initiate collaboration, and let us work together to achieve excellence for your products, building a brighter future together!